Úvod >> Produkty >> Stroje na plast, hliník, kompozit >> PLOTTER, CUTTER, ŘEZAČKA PILART SPEEDY >> PILART SPEEDY ENGLISH

PILART SPEEDY ENGLISH

PILART SPEEDY

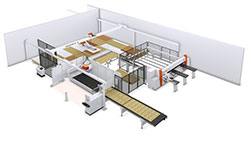

PILART SPEEDY POWERFUL MANUFACTURING MACHINE designed for cutting / milling / labeling of sheet materials in continuous operation. Ideal use of the machine is as a plotter, or cutter. This CZECH PRODUCT is made up of components manufactured exclusively in the EU. Wide accessories, a comfortable control system and tuned CAD / CAM software make this CNC machine a powerful production tool.

PILART SPEEDY is a CNC machine designed for cutting flat materials by cutting with a rotary, fixed or oscillating knife, milling and drilling machining. It is applied especially in the production of shaped parts from a wide range of materials (all types of woven and nonwovens made of natural, artificial, glass, carbon and kevlar fibers, prepreg, aramid, kevlar, dyneema, various types of foil, single and multilayer cardboard, polyurethane foam, honeycomb and foam boards, insulating materials, leather, rubber, soft PVC, floor coverings).

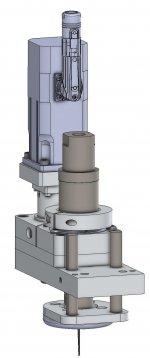

The cutter can be equipped with one or two "Z" slides with a quick-release system for interchangeable units. A machine with one "Z" support is suitable where there is no requirement for automatic replacement of work units in one work cycle. On the other hand, a machine with two "Z" supports is suitable where it is necessary to replace the work unit automatically between 2 operations, eg cutting and subsequent grooving in the production of packaging from cardboard or corrugated cardboard.

Pneumatic oscillating knife

Suitable for:

- foam and honeycomb materials for the production of composites

- kevlar, aramid, dyneema

- foam materials for the production of packaging

- rubber and various types of sealing materials

- floor coverings (PVC, vinyl, carpet, etc.)

- cardboard and corrugated cardboard

- layered textiles (manufacture of wearing apparel and other textile products)

Technical parameters of the oscillating knife:

Max cutting thickness 0 - 50 mm

Working speed 2 - 30 m / min

Operating frequency 150 Hz

Working stroke 2 - 7 mm

Air consumption 20 - 75 l / min

Ultrasound DUKANE

Suitable for:

• rubber and sealing materials

• kevlar, aramid, dyneema

• glass and carbon prepreg

Technical parameters:

max. thickness of cut material 0 - 50 mm

working speed 2 - 30 m / min

operating frequency 20 kHz

generator power 600 W

air consumption 10 l / min

Powered rotary knife

Suitable for:

• glass and carbon prepreg

Technical parameters of the rotary knife:

max. thickness of cut material 0 - 3 mm

working speed 2 - 50 m / min

spindle speed 6 000 – 15 000 rpm

power consumption 1 050 W

diameter of the driven rotary knife 32 mm

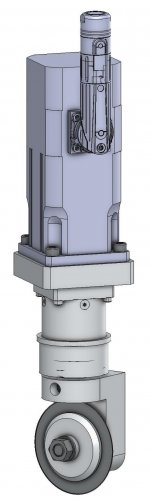

Rotary knife, creasing and perforating wheel

Suitable for:

• glass and carbon fabric (roving)

• rubberized fabrics

• insulation materials

• cardboard perforation

Technical parameters of the rotary knife:

working speed 10 - 50 m / min

wheel diameter 60 mm

Towing knife

The towing knife is designed for harder and hard materials that are able to withstand force during cutting,

which the knife derives by its movement. The head is equipped with a continuously adjusted depth of cut limiter.

Suitable for:

• cardboard and corrugated cardboard

• thin plastic plates of various types

• thin plywood

• magnetic foils

• various sealing materials

Technical parameters of the towing knife:

working speed 10 - 50 m / min

Marking

Flexible compensation pen-type pen for different types of pen is especially applicable for marking of parts for subsequent technological processes. There are pens with very durable ink at 0.3, 0.6 and 1 mm line thicknesses. It is also possible to choose from a wide range of colors.

CNC milling

The milling unit with spring loaded glider and integrated suction is designed especially for cutting of shaped parts by milling from sheet materials.

Milling is possible in a wide variety of materials such as wood, plywood, plastic boards, sandwich panels, composite boards, foam boards, etc.

A high-quality KRESS spindle with variable speed control makes it possible to clamp the milling tools up to a diameter of 8 mm.

The most important part of the milling unit is the flexible glider, which makes it possible to milling materials with a thickness of 0.3 - 10 mm.

This system provides material pressure to the substrate during milling. Part of the milling unit also includes a chip extraction system directly from the cutting point.

Technical parameters of CNC milling:

Spindle speed 10 000 – 25 000 rpm

Power input 1050 W

Maximum tool diameter 8 mm

Diameter of the extractor 40 mm

Probe for measuring tool length automatically

Automatically measuring the length of the tool with the touch probe significantly reduces the time required to set up the machine. When using the probe, you set the machine very quickly and avoid any errors that may occur during manual measurement.

Focus laser

The laser displays a cross on the work surface that allows you to quickly set up the machine. The laser in manual mode using the center cross simply sets the zero point.

The CNC886 control system has a clear dialog for this function that allows you to specify the displacement and rotation of the machine coordinate system. Therefore, it is not necessary to place the product on the machine in the desired position and to align it parallel with the coordinate system.

PILART SPEEDY comes standard with a vacuum clamping system. The work surface consists of longitudinally folded Al profiles with integrated vacuum distribution. The individual sections are equipped with shut-off valves, which can be closed arbitrarily and thus define an active clamping zone.

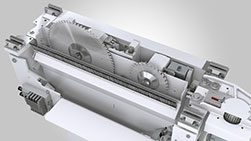

Control system CNC886

PILART SPEEDY is equipped with a very reliable and long-lasting experience tested by the full-digital CNC886 control system running on the Windows platform RTX and interpreting standard ISO programs.

Control of all functions is displayed on the high resolution touch panel LCD panel and with 10-point control.

The control panel has a toughened glass surface, which guarantees a very long life and high scratch resistance.

Operation of the CNC 886 is very pleasant and intuitive.

CAD/CAM Software

Easy-to-use vector drawing and editing tools with powerful 2D machining strategies for CNC cutting, milling, drilling or engraving.

Cut2D PRO provides a powerful but intuitive software solution for cutting parts on a CNC router. Cut2D PRO includes tools for 2D design, editing and effective calculation of 2D toolpath.

The software can import 2D designs from other programs, but also provides a complete set of drawing and editing tools. Toolpath options cover all typical 2D operations such as profiling, pocketing, engraving and drilling. Each strategy makes it possible to adapt the operation to specific requirements. In addition, all paths can be displayed to show what the cut-off part looks like, allowing immediate inspection.

stáhnout PDF

stáhnout PDF